[News] GILLION: High-Grade Adhesives for Electronics Manufacture and Beyond

GILLION: High-Grade Adhesives for Electronics Manufacture and Beyond

Source: Taiwantrade | Updated: 14 April 2021

Kaohsiung-based Gillion first began operations in 2004, designing equipment for product manufacture. Early collaborators included sportswear giant Adidas, who commissioned product testing equipment just four years after launch.

Since then, their ambition has evolved into becoming the one-stop shop for high-grade adhesives. With this goal now at the heart of their work, they have rapidly grown both their production capacity and customer-base, offering their unique services to clients and suppliers across the globe.

What are UV and Thermal Release Adhesives?

Regular adhesives one might buy from local stores, like Cellotape, are pretty ubiquitous. But when it comes to advanced parts processing and manufacture, the simple kind of adhesives we might use to wrap a parcel simply won’t cut it.

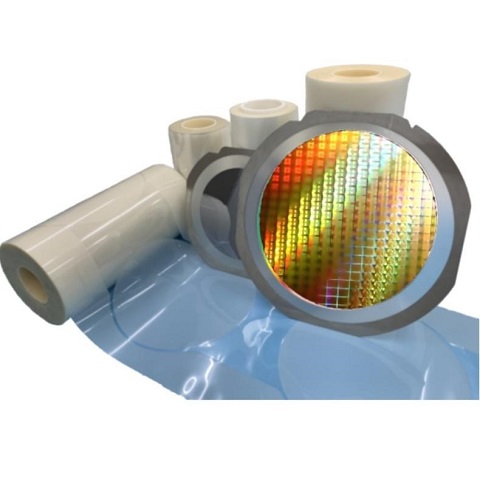

UV-release tapes are a type of dicing tape in which the adhesive is broken by exposure to UV light. This enables the use of an extremely strong adhesive during the manufacture of electronic parts, like cutting and processing - ensuring the optimum operational environment for the material the tape is attached to.

As it turns out, Gillion produced Taiwan’s first UV-release tape back in 2010.

Similarly, thermal release tape offers an extremely strong adhesive for use during polishing, mounting, flipping, and so forth. As the name suggests, the adhesion here is broken by exposure to a certain temperature, allowing it to be easily peeled off without leaving any residue behind .

UV tapes. Image courtesy of Gillion.

Mod-Shop: Customizable Applications for Tape

‘Though our best-selling products are our UV and thermal-release tapes, we have a number of other adhesives we’ve worked hard to perfect,’ says Vice-President, Carven Lin. ‘Our tapes are particularly apt at clean transfers – zero residue is left after removal.’

Among Gillion’s latest developments are an antistatic tape and a double-sided tape, which can have different types of adhesion on either side.

‘Of course, our extensive customization options allow for clients to modify their orders, so that the tape is perfectly suited to their needs. Customer satisfaction is our priority, so we value two-way communication and collaboration on products.’

Thriving During the Pandemic and Looking to the Future

In contrast to other industries, the semiconductor market quickly adapted to the curveball thrown by the COVID-19 pandemic, reportedly experiencing a growth of 7.3% in 2020.

Since high-grade adhesives are fundamental to semiconductor production, Gillion has seen its own fortunes on the up-turn since the start of the pandemic.

‘Since the demand for semiconductors and other high-end electronics components actually increased during the pandemic, our own operations also grew,’ says Lin. ‘We were quick to implement effective ways of dealing with the pandemic, seizing the opportunity to expand our production capacity and respond to customer demand.’

Gillion headquarters. Image courtesy of Gillion.

Spurred on by their successes in spite of the pandemic, Gillion is now looking to expand in other territories to meet the rising demand for semiconductors.

‘Our products are most popular in China, but much of southeast Asia has a strong semiconductor manufacturing market, including places like Singapore and Malaysia. Hence, we are keen to focus on expanding our presence there, as well as in the US, where electronic component manufacture remains a lucrative industry.’

https://www.taiwantrade.com/news/gillion-high-grade-adhesives-for-electronics-manufacture-and-beyond-2317642.html